For Industrial

Solar lighting & LuminoKrom photoluminescent floor marking for warehouses & yards

Industrial facilities face strict WHS obligations. LuminoKrom photoluminescent floor marking provides a fail-safe visual layer that remains visible during power failures - critical for emergency egress and forklift-pedestrian separation zones. Solar lighting provides reliable perimeter and yard lighting without expensive trenching through hardstand areas.

The Challenges You Face

Traditional lighting infrastructure is expensive, complex, and vulnerable.

Forklift-pedestrian collision risk in shared traffic zones

Power failure emergency visibility and evacuation

High-traffic floor marking durability and wear

WHS compliance requirements under SafeWork Australia guidance

Outdoor yard and loading dock lighting in harsh conditions

Floor markings that disappear when lights go out

Our Dual-Technology Approach

We combine advanced solar lighting with photoluminescent marking for a complete, resilient solution.

Solar Lighting

Active Illumination

Key Benefits

- Hardstand LightingLight up concrete yards without expensive trenching.

- SecurityMotion-activated lighting for gates and perimeters.

- FlexibilityMove lights as site layout changes.

Common Use Cases

Photoluminescent

Passive Safety Marking

Key Benefits

- Forklift SafetyClearly define separation zones even in low light.

- Blackout EgressGuides staff to exits instantly when power fails.

- DurabilityChemical and oil resistant for heavy industrial use.

Common Use Cases

LuminoKrom Specifications

Technical specifications for photoluminescent marking in industrial applications.

Traffic Rating

Forklift and heavy traffic rated

Chemical Resistance

Oil, hydraulic fluid, cleaning agents

Cure Time

Varies by substrate and conditions

Glow Duration

Up to 10 hours

Safety Planning

Supports emergency egress marking

Lifespan

Varies by surface and traffic

Industrial Safety & Operational Lighting

Industrial sites operate around the clock and involve heavy machinery. Lighting here isn't just about convenience; it's a critical safety control. Solar lighting and photoluminescent marking provide redundancy and resilience that grid-only systems cannot match.

Lighting Remote Hardstands

Many industrial sites have large, unlit hardstand areas used for storage or truck marshalling. Running mains power to these perimeters often involves cutting through thick reinforced concrete, which is incredibly expensive. High-power solar area lights (like the SO-AREA 20W) can be mounted on poles bolted to the concrete surface, instantly turning a dark "dead zone" into a usable operational area.

Passive Safety in Blackouts

When the power goes out, warehouses can become dangerously dark, disorienting staff and hiding hazards like forklift tines or steps. LuminoKrom floor marking provides an "always-on" visual guide. It charges from your standard high-bay lights during the shift and glows immediately if the lights fail, clearly defining walkways and exits without needing batteries or generators.

Forklift-Proof Floor Marking

Standard line marking paint often wears off within months in high-traffic forklift aisles. Photoluminescent marking systems designed for industrial use are extremely durable. By embedding the glow technology into a high-performance resin, you get a line that withstands tyre abrasion and cleaning chemicals, reducing the frequency of re-painting shutdowns.

Common Questions

Will solar lights work for 24-hour shift operations?

Solar lights are best suited for "dusk-to-dawn" security lighting or areas with intermittent use (sensor activated). For 24/7 continuous high-lux task lighting inside a factory, mains power is still the standard. Solar is the perfect partner for the outdoor yards, gates, and perimeters.

Can LuminoKrom withstand forklift traffic?

Yes. When applied correctly on a prepared surface, industrial-grade photoluminescent coatings are highly resistant to abrasion from rubber tyres and pallet jacks.

Does the glow paint need sunlight to charge?

No. It charges effectively from standard indoor artificial lighting (LED, metal halide, etc.). As long as the lights are on during the shift, the paint will be charged and ready if the power fails.

How do we install the solar poles on concrete?

We typically use a "chem-set" method. Threaded rods are chemically bonded into holes drilled in the concrete, and the pole base plate is bolted down. It's fast and extremely strong.

Can forklifts drive over the marking?

Yes. LuminoKrom is rated for forklift and heavy traffic, designed to withstand industrial operational demands.

How quickly can we return to operations after application?

Foot traffic can resume in 2-4 hours. Forklift and vehicle traffic in 6-8 hours. Full cure in 24-48 hours.

Does it meet WHS requirements?

LuminoKrom can complement your site traffic management system and supports emergency egress visibility requirements.

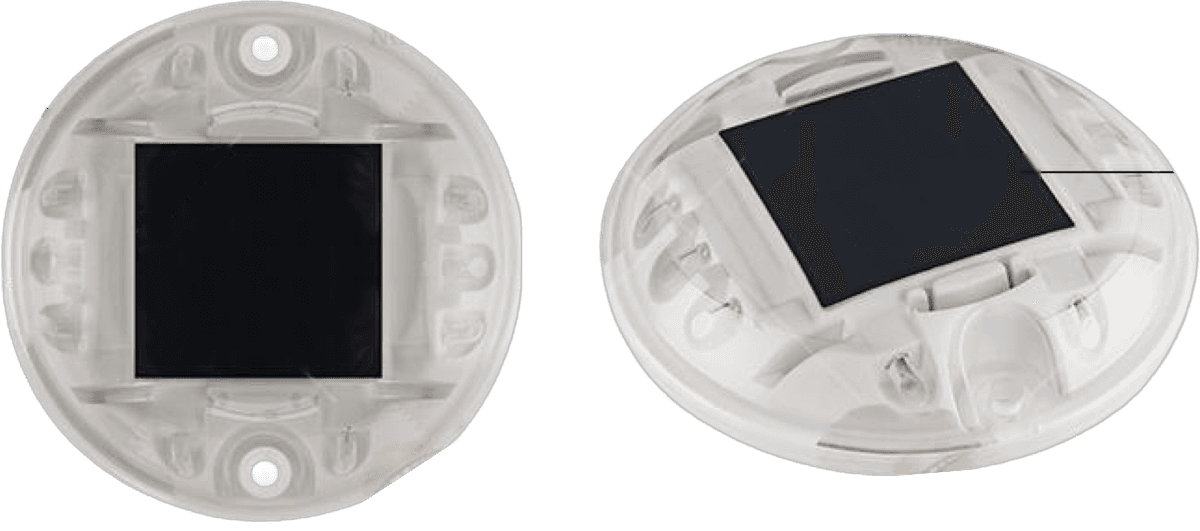

Recommended Products

Products commonly used for industrial applications.

Related Articles

Guides and insights for industrial applications

Ready to Get Started?

Tell us about your industrial project and we'll recommend the best products for your needs. No obligation.