Industrial Yard Lighting for Night Shift Safety

Proper lighting supports night shift worker alertness, confidence, and productivity. Learn how commercial solar lighting improves work environments and meets WHS requirements.

Modern solar area lights provide consistent illumination for industrial operations without grid dependency

The Night Shift Safety Challenge

Australian industrial operations increasingly run around the clock. Warehouses, distribution centres, manufacturing plants, and logistics yards rely on night shift workers to maintain productivity. Creating the right working environment — including proper lighting — is essential for supporting these workers.

Safe Work Australia recognises that adequate lighting is a key control measure for shift workers. Well-lit environments support alertness, visibility, and overall workplace comfort.

Supporting Night Shift Worker Wellbeing

Source: Safe Work Australia guidance on shift work and workplace lighting

Lighting Standards for Industrial Yards

Australian Standard AS/NZS 1680.1 provides minimum illumination requirements for industrial workplaces. Meeting these standards isn't just about compliance—it directly impacts worker safety and operational efficiency.

Industrial Lighting Requirements (AS/NZS 1680.1)

Benefits of Solar Industrial Lighting

Grid Independence

Operates during power outages, storms, and grid failures when safety lighting is most critical

Zero Trenching

Install anywhere in the yard without expensive cabling or disruption to operations

Zero Energy Costs

Eliminate thousands annually in electricity costs for yard lighting

Consistent Coverage

Motion sensors ensure full brightness when workers are present, dimmed standby otherwise

Industrial Yard Lighting Checklist

- Overhead area lights

- Motion activation

- Min 100 lux at ground

- Path marker lights

- Intersection lighting

- Clear sightlines

- Bollard lighting

- Entry/exit illumination

- Emergency egress paths

- Rack aisle lighting

- Signage illumination

- Hazard area marking

7 Steps to Safer Night Shift Operations

Key Takeaways

- Proper lighting improves night shift worker alertness and confidence

- Lighting should be designed to meet applicable AS/NZS standards for the specific area

- Solar industrial lights eliminate trenching costs and operate during power outages

- Visibility improvements support productivity and operational efficiency

- Motion-sensing lighting can balance worker comfort with energy use

Industrial-Grade Solar Lighting Solutions

High-output solar lights engineered for demanding industrial environments

Area Light 20W

High-lumen solar area light with intelligent working mode

$288.00AUD

Postage + GST included

LuminoKrom Path Paint

Photoluminescent path marking paint

Request quote

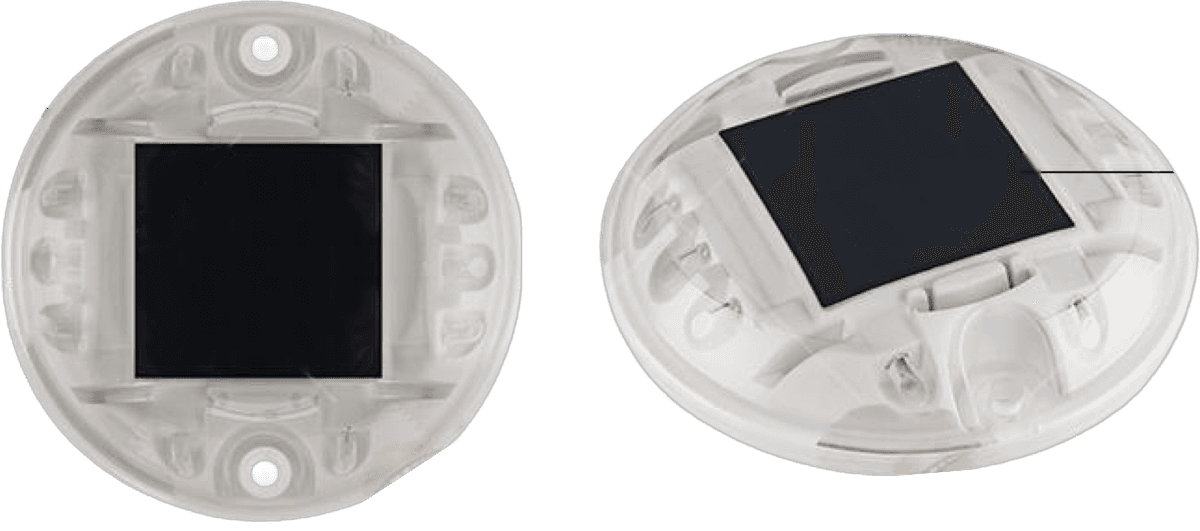

Solar Path Marker Studs

High-visibility solar path markers for safe navigation

$38.00AUD

Postage + GST included

Sources & References

Improve Night Shift Safety

Commercial-grade solar area lights for industrial yards, loading docks, and warehouses. No electrician required.

Related Articles

Continue exploring our solar lighting guides and resources